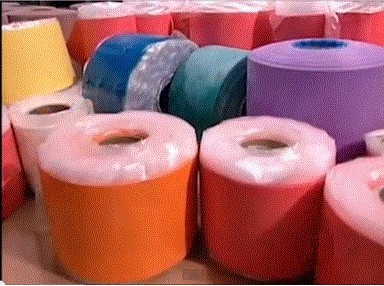

Rubber Compound

Rubber Products

Rubber compound is raw rubber that has been mixed with mineral fillers, processing oils/ aids, accelerators etc. by using a rubber milling machine such as open mill, kneader or banbury, which if heated at sufficient temperature and time will turn into a rubber finished products ( permanent vulcanized rubbers).

Available rubber types :

- NR

- IR

- SBR

- BR

- EPM

- EPDM

- IIR

- BIIR

- CIIR

- NBR

- NBR+PVC

- CR / NEOPRENE

- HNBR

- CSM

- ACM

- AEM

- PU

- VMQ

- FMQ

- FKM

- FFKM

Rubber Compounds are selling with the following specifications:

- Supply-form: sheet covered with HDPE-foils or antitack-powder . Width: 2 - 50 cm ; Length: ≤ 100 m; Thickness : 0,5 - 20 mm

- Lifetime : ( Depend on rubber-types used, storage place and room temperature.)

usually :5 - 30 days

- Color : All kind of color, including transparent and fluorescents.

- Scorch-time ( T=150°C ) : from 1,5 - 30 menit (*)

- Cure temperature: from room temp. to 250°C (*)

- Curetime ( T=150°C) : ≥ 3 menit (*)

Technical Specifications: custom specs.

IRHD ( Hardness ); Tensile strength; Elongation at break; Abrasion resistance; Tear resistanceService temperature; Compression set; Rebound resilience; Chemical properties; Electrical & Electrostatic propertiesCall us for consultation !